Two stage process with no titration

Introduction

Many experienced brewers will have tried to push a reluctant single stage reaction to 100% completion after a failed 3/27 test by adding more methanol and catalyst into the mix. However, often the calculated amount of catalyst is insufficient, and the mix just seems to absorb it without much extra conversion taking place. Ultimately, too much catalyst may be added, producing the dreaded jelly/soap mix. These problems can be caused by not dewatering your feedstock fully, poor titration technique, or other oil contaminants.

A non-titration two-stage process avoids non-conversion scenarios as any unknown factors are normally taken care of by the first stage. By making your second stage methoxide based on the test results after the first stage, all variables are removed. Two-staging also yields excellent conversion of the source oil because it accounts for both the reversible nature of the reaction, and the water produced by the reaction. If your oil is very poor you may need to go to a third stage or even a fourth - what you are doing is a softly softly approach instead of hitting the oil with a large load of catalyst and risking a batch of jelly.

Note this process is not a reason to use known wet oil, try to dry as much as possible as you normally would.

Many people have said that you must do titrations and that the 3/27 test is not quantative so can't be used in this way. However, the same sorts of things were said about whole batch demeth and now that is an accepted part of the process.

The process

No need to Titrate (but you can if you want to)

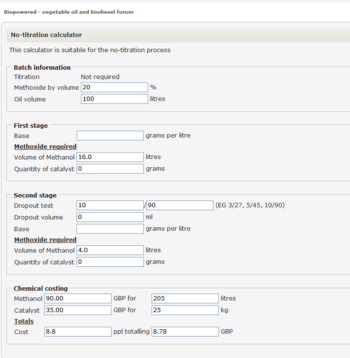

- Make your first stage methoxide solution with base amounts 3.5g/l for NaOH or 5g/l KOH x full batch size + 80% of normal methanol amount.

- Put this first stage methoxide mix into the processor at normal reaction temperature, and mix for an hour.

- Stand for 20 minutes and drain off the glycerol into a clean container, and seal.

- Do your 3/27, 5/45 or 10/90 test and measure the amount of drop out.

- Determine the amount of unprocessed oil in your batch from the dropout.

- Make up the second stage methoxide by mixing "unprocessed oil volume x 20%" methanol with "unprocessed oil volume x base" catalyst.

- Now mix as normal for second stage

- Do another 3/27 test after 30 minutes to check conversion. If this does not give a clear pass continue mixing for another 30 minutes - it should give a clear pass. If not go to step 4 above and repeat but with minimal methanol.

If you know you normally have feedstock titrating above 4 you can raise your first stage base to 6 or 7g/l NaOH. Alternatively you can opt for a multi stage process which will help reduce the amounts of soap and glycerol.

If you find you are not getting any glyc dropping from the 1st stage add some more methoxide in stages of 1g/L of oil and circulate for 30 min's or so, keep doing this until your glyc drops, note the amount needed and use this for your 1st stage amount for future batches assuming you use oil from the same suppliers as your test batch.

If your oil is very variable in quality you may need to titrate each batch to determine stage 1 methoxide, you will still get the benefit of less chemicals used but won't get the easy life a consistent supply of similar oil would give. Glycerol_wash will help a lot if this is the case.

If your process involves whole batch demeth or water prewash, the stage one glycerol should be returned to the mix first. Although you may be concerned that the first stage NaOH glycerol might solidify while out of the processor, the methanol present should keep it liquid and it should stay warm for some time.

Otherwise, stand for a further 20 minutes, and drain off any further glycerol present, leaving just biodiesel ready to settle or filter.

After extensive testing it has been found that first stage catalyst of 3.5g/l for NaOH or 5g/l KOH give good results. Adjust the levels of catalyst to get around 60 to 75% conversion on the first stage, this will ensure you are producing as little soap as possible while being able to achieve a good pass with two stages.

It seems that most of the people who have been trialling this method are getting around a 25% reduction in catalyst use and much less soap produced in the process. It has also been reported that some people are getting more biodiesel out than WVO put in.

Why two stage reactions work

The conversion process is a balanced, reversible reaction that sits somewhere between vegetable oil + methanol and biodiesel + glycerol. We push it to the biodiesel + glycerol side by using an excess of methanol, but as the methanol is consumed and more glycerol is present, it becomes harder to get that last little bit of vegetable oil to tip over to biodiesel. This is because of the glycerol present in the mix, constantly trying to push the reaction back the other way, despite the excess methanol. It's a bit like working against a spring.

By stopping mid-reaction and removing the excess glycerol, the resistance to converting the last bit of vegetable oil is removed, and the reaction completes easily.

Additionally, the process of making methoxide produces water which catalyses consumption of methoxide by the formation of soap. Removing the glycerol will take the majority of water away with it to the benefit of the second stage.